5 Star Rating

Orders Deliver

PhD Experts

Support

Privacy

Top Quality

Number Of View : 51

Download : 0

Pages: 14

Words : 3296

Refer the reputed journals/magazines for latest research/innovativeness of the technologies/ treatment operations of process industries.

Introduction

Energy has become fundamental to the growth and development of the world. Without energy, the existence of the world cannot be imagined. The energy trends of the world such as higher demand and price for energy, structural changes in the oil and gas industry, differences across regions, demand for energy security, and prospect of irreversible change in the climate show the urgency of transition to efficient, low-carbon, as well as environment friendly energy sources (Bioenergy, 2010). Therefore, there is a need to identify an alternative energy source which renewable and locally available.

In search of the alternate energy source, scientists are focusing on bioenergy as it is one of the most significant and reliable energy sources which can be used in the short and medium-term. There are four main sources of biomass such as forest, agriculture, waste, and others. Biomass is the fourth-largest source of energy in the world after coal, oil, as well as natural gas. Biomass is also the largest source of renewable energy and at present, it is the most important source of energy that can be used to produce different types of energy (Guo et al., 2015). Biomass with other renewable energy sources is capable of providing the entire energy services needed in today's world. There are two most important advantages of biomass energy such as renewability as well as versatility. The biomass resources are widespread as well as common throughout the globe as compared to other renewable sources of energy. Apart from this, the sustainability potential of global biomass for energy has been recognized extensively. For example, the global primary production of biomass is equivalent to 4500 EJ of solar energy captured annually. At present, 225 EJ or 5% of the biomass energy can cover almost half of the total primary demand for energy of the world.

Literature review

According to Creutzig et al., 2015 biomass has been the major source of energy since the beginning of the across the globe. It is the primary source of energy for almost half of the population of the world. Wood biomass represents a significant proportion of the energy supply in the rural areas and it is a major source of renewable energy in the third-world or developing countries. Biomass energy is not important only for meeting the demand of the world for energy but it is also important for the sustainable development of the world. It helps in protecting the environment. Climate change is a major concern all over the globe. Considering the factors responsible for climate change, it is important to focus on the source of biomass. The use of biomass energy will reduce the use of fossil fuel which further will reduce the emission of carbon in the environment. Thus, the use of biomass energy should be promoted across the globe.

Biomass energy is renewable energy which can be extensively used across the globe. Biomass energy can serve several purposes or can provide energy for different services. It can be used to produce electricity by driving turbines. It can also be used for transportation in the form of ethanol and biodiesel. The key advantages of biomass energy are that it significantly helps in reducing the emission of carbon in the environment (Ort et al., 2015). However, it is not a completely clean source of energy. It also contains some greenhouse gases but the advantages of it outweigh the disadvantages as compared to other sources of energy.

Process operation/functionality

Biomass is a renewable source of energy and organic material which comes from animals and plants. It contains energy or stored energy from the sun. The energy from the sun is absorbed by plants in a process which is called photosynthesis. The chemical energy is released as heat when biomass is burned. There are different methods of using biomass. It can be burned directly. It can also be converted to biogas or liquid biofuel and burn as fuel (Solomon et al., 2019). The following are examples of biomass and their uses;

• Food and wood waste: it is used to burn to generate electricity. It can also be converted into biogas.

• Wood and wood processing waste: it is used to provide heat o buildings. It is also used to generate electricity as well as process heat in industries.

• Crop (agricultural) and waste materials: it is directly burned as fuel. It can also be converted into biofuels.

• Human sewage and animal manure: it is converted to biogas that can be burned as fuel.

From the above discussion, it is clear that there are three methods of using biomass. It can be converted to electricity, thermal energy, as well as fuels for power. The following are the major methods of converting biomass; direct combustion, liquidation, as well as gasification of biomass.

Direct combustion

This is traditional as well as the most common way to generate heat from biomass. The efficiency of the direct combustion of biomass in developing countries is only 10 to 15%. A stove is used in the process of generating heat from the biomass in direct combustion. The stove of direct combustion consists of a combustion chamber, chimney, smoke circulation passage, stove door, fire fencing ring, air inlet as well as grate (Quispe et al., 2017). The stove is designed in such a way which can enhance the intensity of the thermal radiation. It is also designed to reduce the loss of the entire combustion as well as enhancement of reflection in the combustion chamber in the inner stove. In order to enhance the efficiency of the direct combustion, high-efficiency combustion equipment has been developed. Sulphurized-bed equipment is one of the high-efficiency combustion equipment. In Sulphurized-bed equipment, wood is cut into small pieces. The wood pieces pass through the Sulphurized bed in very little time and the combustion process starts in the equipment (Bergthorson et al., 2015). The incomplete burned pieces of wood after combustion returned to the Sulphurized bed with the help of a smoke exhaust system.

Apart from this, there are small and medium-sized boilers which are also used for direct combustion. These boilers take wood and residues as fuel.

Gasification of biomass

Pyrolysing technology is an optimum utilization technology of the gasification of the biomass. Biomass is transferred through thermal chemical action to high-grade combustible gas in the gasification equipment at high temperatures. As a result, gas is produced which can be used for the purpose of heating, electricity generation, drying, as well as thermal insulation. As the gasification medium, the biomass gasification equipment takes air until now. Such type of gasification equipment is characterized by a simple structure. It is also convenient to use or operate. It has been found that almost all biomass is transferred to gas fuel with the help of gasification equipment. It mainly consists of CO2, CH4, CO, and H2 (Shahbaz et al., 2017). The ground biomass cuts into smaller pieces and put in the gasification chamber. It slides slowly from the top of the gasification chamber in the process of gasifying. From the bottom of the gasification chamber, the oxidizer flows upwards. It passes through the biomass in order to gasify it. The temperature of the output gas is very high and it can reach 600oC.

In order to transfer biomass into liquid fuel, the following methods are used; biochemistry, chemical, mechanical, and thermalization method. The biofuel produced from the biomass is relatively costly as compared to fossil fuel. The recent technologies are not capable of producing biofuel efficiently and hence it requires a breakthrough in biomass liquidation technology to provide biofuel at a relatively lower price than the fossil fuel. Methanol is used as a substitute for diesel. Plant oil is esterified to methanol. Only 0.05 tons of methanol can be esterified per ton of rapeseed oil. 0.05 tons of methanol can produce only 0.32 tons of the substitute for the diesel (Correa and Kruse, 2018). Thus, it is not a feasible solution to produce the substitute of diesel using biomass with the help of available technologies.

Experimental setup

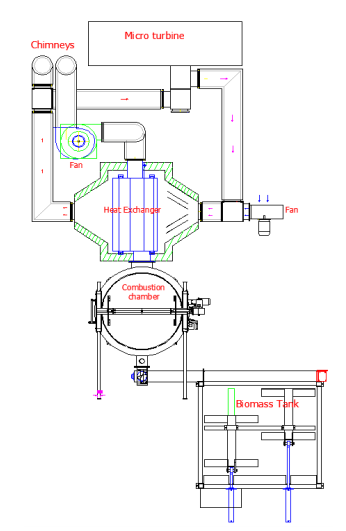

The experimental setup helps in proving insight to develop equipment to produce biomass energy. With the help of this experimental setup, a multi-fuel biomass energy plant can be installed. The experimental setup focuses on a combustion chamber, biomass storage, a loading section, air or exhaust gas heat exchanger, and a gas turbine.

The storage tank will be filled with the pieces of wood with the help of a loading hopper. The pieces of wood will be pushed by a rake system. The wood chips will move towards a cochlea which will be driven by a 1.5 kW power electric motor. In order to generate heat, fuel will be supplied to the burner through the combustion process. In the section of the heat exchanger, the thermal energy can be exchanged to air from exhaust gases. A cyclone will be installed at the output of the exhaust gas dust. It will reduce the particulate as well as fly ash emission (Ergas et al., 2017). There will also be a suction fan. With the help of the suction fan, the exhaust gas will be evacuated through the pipeline which leads to the chimney. There will also be a microturbine installed in the multi-fuel biomass energy plant. The installed turbine will produce 100 kW of electricity. The consumption of electricity by the plant is excluded from 100 kW. Two different operating configurations are possible for the microturbine. It will be connected to the biomass combustion chamber with the help of exhaust gases heat exchanger. In operation, an electrical efficiency with natural gas above 25 percent is guaranteed from the system. A control system will be installed to measure as well as manage gas and rates of airflow and temperature. There will be several thermocouples installed in the multi-fuel biomass energy plant. It will help in detecting the values of temperature in the different section such as combustion chamber, inlet air, cement which surrounds the chamber of combustion, and exhaust gases monitoring on the chimney (Verma and Suthar, 2016). There will be a monitoring system as well for exhaust gas analysis. Moreover, specific sensors will be inserted inside the pipeline. It will allow determining the rates of flow of the fluids.

(The layout of the plant)

There are four phases of the ignition protocol of the combustion. These phases represent the working cycle. The following are the phases of the ignition protocol of the combustion which is powered by solid biomass.

• Ignition phase: this phase is characterized by flue gas temperature of up to 120oC

• Heating phase: this phase is characterized by the temperature of the exhaust gases up to 300oC

• Steady-state phase: it is characterized by up to the leaving air temperature of the exchanger equal to 750oC

• Extinguishing phase: it is characterized by flue gas temperature of up to 100oC

The following steps represent the on/off protocol;

• The automatic cycle starts: the automatic cycle start phase lasts 20 minutes. It enables the hydraulic hopper pump, the burner loading screw, hopper rake, the hopper screw, and the load solenoid valve.

• Ignition of the oil burner

• Loading the biomass up to filling the cochlea

• Flame ignition of the biomass: this phase lasts 15 minutes. It helps in checking the presence of the flame from the inspection peephole. It is located on the burner wall.

• Ignition of the depressor

• Starting the loading auger after 5 minutes. It is done with 5 cycles which consist of 2 minutes pause and 2 minutes loading. It also helps in checking whether cochlea is remaining in operation or not.

• Automatic shutdown of the pilot plant: it happens in case the temperature of the exhaust gases reduces up to 100oC

• Starting the heating as well as steady-state phase. In this phase, the rakes of the grid, the oxygenators, the cochlea, and the fan located downstream of the exchanger to transport the ash from the burner are activated.

• Start switching off from the control panel: this phase ends as the temperature of the exhaust gases reach 100oC.

Innovation, creativity, and commercialization

Technological innovation, as well as advancement, is moving the industry of biomass or bioenergy forward. As the need for energy is increasing day by day, there is a need to produce enough energy to meet the increasing need for energy. Technological innovation and advancement will help the world to meet the growing demand for energy. Biomass is a renewable source of energy and it can be used to meet the need for energy of the world. Innovation is the way of working and achieving sustainability through increasing the efficiency of renewable energy.

In this respect, scientists have achieved three breakthroughs which show how innovations in the bioenergy field are energizing the landscape of energy. The first and foremost breakthrough achieved by scientists is the renewable jet fuel. The renewable jet fuel can be produced from industrial waste gases. Virgin Atlantic a commercial airline has also announced to use renewable jet fuel. In order to produce fuel for airplanes, carbon-rich industrial waste gases are used such as carbon monoxide (Lundmark and Bäckström, 2015). Carbon monoxide is produced from steel production. The introduction of this process has paved the way to provide a sustainable source of renewable jet fuel. It will significantly reduce the emission of greenhouse gases from the transportation sector. It does not only provide a sustainable source of energy but also a solution for managing industrial waste.

"ALGAL TURF SCRUBBERS" fuel cars and clean up pollution is another breakthrough achieved by the scientists in the field of bioenergy. The power of microorganisms is being evaluated to benefit the environment. The ways of developing Algal Turf Scrubbers are being investigated. It would be developed as a long thread-like algae which can be installed near wastewater or stormwater runoff sites (Fevolden and Klitkou, 2017). It will absorb excess nitrogen as well as phosphorus from the agricultural sites. There is a chance that excess nitrogen and phosphorus can harm the aquatic ecosystem. But Algal Turf Scrubbers can deal with this issue. The algae can be converted into biofuel.

Biofuel from sludge waste is the third breakthrough in the field of bioenergy. The scientists are working to develop a technology that can be used to produce biofuel from wet wastes at water treatment plants. In the United States of America alone, 7 million tons of try sewage sludge is produced in the process of treating municipal wastewater. It is very costly to manage and dispose of the produced sludge. Thus, converting sludge into bioenergy will provide an economically viable alternative energy source (Refsgaard et al., 2017). It will transform the water treatment plants into the water resource recovery plants or facilities.

Commercialization

Biomass is widely spread all over the globe. It is one of the renewable energy sources which can mitigate the issue of the crisis of energy and provide sustainable energy to the world. However, the efficiency of bioenergy is in question. But it is believed that innovation and advancement of the technology can improve the efficiency of bioenergy and hence commercialization of bioenergy can be done on a large scale. Most importantly, the government should be concerned about producing as well as using bioenergy for domestic and industrial purposes. The people should be educated about the importance and need for bioenergy (Bakhtiar et al., 2019). They should be motivated and encouraged to use bioenergy for fuel and other purposes. Apart from this, the government should also encourage entrepreneurs to set up their start-up to produce bioenergy. The government should also simplify the administrative procedures so that the developers can easily enter into this business and produce bioenergy. Subsidized technology and equipment should be provided by the government to encourage new entrepreneurs to start their business in this field. It is not only the responsibility of the government. The industrialist should also join hands with the government to produce bioenergy at a large level. Moreover, the prices of bioenergy is also a matter of concern. It should not be higher than the price of fossil fuel only then the people will go for bioenergy instead of fossil fuel/energy.

Conclusion

Biomass is an important source of renewable energy. Harnessing bioenergy can resolve the issue of the crisis of energy in the world. It has the potential to provide energy and meet the demand for energy in the world. It does not only meet the need for bioenergy but also ensures sustainability. It can protect the environment from greenhouse gases. The burning of biomass does not produce greenhouse gases. However, it is not a completely clean source of energy and some of the greenhouse gases are produced by biomass. But the advantages of biomass outweigh the limitations. Therefore, the production and usage of bioenergy should be done on a large scale.

Recommendation

Biomass has the potential to cover several types of fuels and hence it can meet the demand for energy in the world. Therefore, the production of bioenergy should be encouraged. The competitive environment for self-generation of bioenergy should be enhanced. A tough competitive environment will lead to more production of bioenergy. Innovation and creativity should be encouraged in the field of bioenergy (Tripathi et al., 2016). The efficiency of bioenergy should be improved. The improvement in the efficiency of bioenergy will encourage the developers to enter into this business and hence the production of bioenergy will also increase. The biomass resources should be maximized and make it available to the energy market.

References

Bakhtiar, A., Aslani, A., and Hosseini, S.M., 2019. Challenges of diffusion and commercialization of bioenergy in developing countries. Renewable Energy, 145, pp.1780-1798.

Bergthorson, J.M., Goroshin, S., Soo, M.J., Julien, P., Palecka, J., Frost, D.L. and Jarvis, D.J., 2015. Direct combustion of recyclable metal fuels for zero-carbon heat and power. Applied Energy, 160, pp.368-382.

Bioenergy, I.E.A., 2010. Bioenergy, land-use change and climate change mitigation. Report for policy advisors and policymakers. IEA Bioenergy: ExCo, 3.

Correa, C.R. and Kruse, A., 2018. Supercritical water gasification of biomass for hydrogen production–Review. The Journal of Supercritical Fluids, 133, pp.573-590.

Creutzig, F., Ravindranath, N.H., Berndes, G., Bolwig, S., Bright, R., Cherubini, F., Chum, H., Corbera, E., Delucchi, M., Faaij, A. and Fargione, J., 2015. Bioenergy and climate change mitigation: an assessment. Gcb Bioenergy, 7(5), pp.916-944.

Ergas, S., Zhang, Q., Dixon, P., Lee, E., Jimenez, E. and Bittencourt, P., 2017. Phase II Bioenergy Production from MSW by High Solids Anaerobic Digestion May 2017.

Fevolden, A.M. and Klitkou, A., 2017. A fuel too far? Technology, innovation, and transition in failed biofuel development in Norway. Energy research & social science, 23, pp.125-135.

Guo, M., Song, W., and Buhain, J., 2015. Bioenergy and biofuels: History, status, and perspective. Renewable and Sustainable Energy Reviews, 42, pp.712-725.

Lundmark, R. and Bäckström, K., 2015. Bioenergy innovation and energy policy. Economics of Innovation and New Technology, 24(8), pp.755-775.

Ort, D.R., Merchant, S.S., Alric, J., Barkan, A., Blankenship, R.E., Bock, R., Croce, R., Hanson, M.R., Hibberd, J.M., Long, S.P. and Moore, T.A., 2015. Redesigning photosynthesis to sustainably meet global food and bioenergy demand. Proceedings of the national academy of sciences, 112(28), pp.8529-8536.

Quispe, I., Navia, R. and Kahhat, R., 2017. Energy potential from rice husk through direct combustion and fast pyrolysis: a review. Waste management, 59, pp.200-210.

Refsgaard, K., Bryden, J. and Kvakkestad, V., 2017. Towards inclusive innovation praxis in forest-based bioenergy. Innovation and Development, 7(1), pp.153-173.

Shahbaz, M., Inayat, A., Patrick, D.O. and Ammar, M., 2017. The influence of catalysts in biomass steam gasification and catalytic potential of coal bottom ash in biomass steam gasification: a review. Renewable and Sustainable Energy Reviews, 73, pp.468-476.

Solomon, J., Miller, G.C., Verburg, P., Blank, R. and Cushman, J., 2019. Discerning Agronomic Best Management Practices for the Bioenergy Crop Camelina: A Focus on Water Requirements, Sowing Date and Method, and Nitrogen Application Rate in the Semiarid Environment of Northern Nevada (Doctoral dissertation).

Tripathi, V., Edrisi, S.A. and Abhilash, P.C., 2016. Towards the coupling of phytoremediation with bioenergy production. Renewable and Sustainable Energy Reviews, 57, pp.1386-1389.

Verma, R. and Suthar, S., 2016. Bioenergy potential of duckweed (Lemna gibba L.) biomass. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 38(15), pp.2231-2237.

Limitless Amendments

$09.50 free

Bibliography

$10.50 free

Outline

$05.00 free

Title page

$07.50 free

Formatting

$07.50 free

Plagiarism Report

$10.00 free

Get all these features for $50.00

Enter your email, and we shall get back to you in an hour.